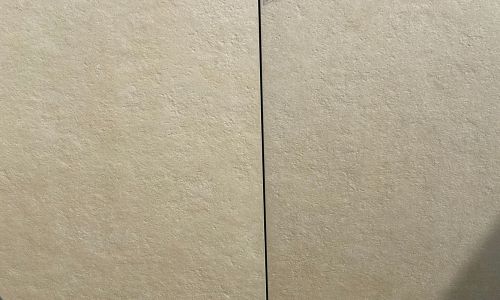

Hardstone - Wood Style Paving - Sleepers - Brown Oak - Single Sizes

Hardstone - Wood Style Paving - Sleepers - Brown Oak - Single Sizes

| Quick Find Code | 049725 |

|---|---|

| Manufacturer |

Hardstone  |

| Manufacturer Range | Hardstone - Porcelain |

| Material |

Concrete (Man Made)  |

| Supplier Colour | Brown Oak |

| Surface Finish | Wood Effect |

| Edge Finish |

Rumbled  |

| Thickness | 40mm |

Calibrated / Uncalibrated  |

Calibrated |

| Thickness Policy | Manufacturer states that size dimensions quoted are nominal and will vary depending on stone and edging. |

| Dimension Policy | Sizes and coverage are those attained when laid with a 15-22mm joint. |

Our standard method of delivery for heavy items is using the pallet delivery network. The delivery will arrive on a lorry with an electric tailift and a hand pump truck.

Access must be made for a lorry (up to 32ft) otherwise additional delivery charges may be payable. You must advise us of any restrictions that will impede the delivery vehicles from delivering the Products. The Products will be delivered to the kerbside outside. Our couriers are not insured to take goods onto your premises without permission. If you require the driver to come onto your property (at their discretion and deemed safe) with the wagon, the Products, or both, this is entirely at your own risk and if the driver or wagon damages anything (including but not limited to, manhole covers, tarmac driveways, block paved drives, flagged driveways / graveled or stoned driveways, grassed areas, walls, pillars, gate posts, gates, trees, hedges, telephone wires, lights) the cost of repair will be your responsibility.

Ensure that the delivery area is flat and solid enough to take the weight of a pallet truck carrying up to 1000kg in weight. Please note Gravel and Grass are not classed as solid and flat. If the delivery area is not flat the driver will require help in getting the pallets off the vehicle. If help cannot be given there will be a redelivery charge to deliver at a time when help can be given. If you live on a hill you will need to call us before you order to find out if our delivery company can deliver to your address. This is for health and safety reasons, usually the easiest method of getting around this is for the order to be delivered to the nearest flat ground. It will be your responsibility to move the goods to your property. Deliveries via hiab or moffet can be arranged but at an additional cost, click for further details.

Smaller items will be delivered via a parcel courier.

All delivery methods will require someone to accept the delivery, check it over and sign that they have been received in good condition. Please note any damages on the delivery sheet / electronic device, do not use the product and contact us straight away.

Next day, AM/PM or even Saturday deliveries can be arranged at an extra cost. Please add your items to the shopping cart for an instant quote.

Pallet Deliveries

After your order has been dispatched you will be contacted on the phone (within 3 days), by your local pallet delivery company in your area, once they receive the goods from our local depot, to book-in a day that is convenient for you. (this will not occur on Timed, Next Day & Saturday deliveries)

Parcel Deliveries

After your order has been dispatched you will receive your goods within 2-3 days. No telephone book-in will occur.

Remember when handling your goods:

- Take care when removing the packaging / banding and also when removing the product out of the crate / pallet as they may have weakened during transit and could be unstable.

- The product is quite heavy, and some larger products can weigh a lot. Consider this when arranging the delivery, as you may need appropriate lifting equipment, or an extra pair of hands.

To ensure you prepare adequately for pallet deliveries please watch the video below for a comprehensive guide and also read the full delivery guide https://lsd.co.uk/delivery-details

Our sister company Hardstone was first founded in 2003 by Robert Pickard. With 25+ years experience in the Sheffield builders merchant scene under his tool belt, his expertise in and extensive knowledge has allowed him to build up great trading relationships with suppliers in the UK, India, China and Italy to name a few.

Because of these excellent relationships and smaller supply chain it allows us to offer a much better price. It also allows us to focus highly on developing practical solutions to ethical trade that deliver benefits for workers. Hardstone ensure that the suppliers are all members of the ETI which is a unique organisation bringing together global companies, trade unions and NGOs

With ranges extending from more traditional natural sandstone and limestone to the contemporary and stylish porcelain paving.

Frequently Asked Questions and Answers

OTHER COLOUR OPTIONS

-

Hammerstone Beige - Paving Slabs

Hammerstone Beige - Paving SlabsFrom £24 .12 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack Patio Pack 19.37m2

£26.98

64 Out of stock900 x 600mm 21.60m2

£24.12

40 £520 .92 per packinc VATMixed Sizes - 1m2 1.00m2

£32.66

4 Out of stock900 x 600mm - Individual - 1 £13 .80 per slabinc VAT -

Vesuvius Black - Single Sizes

Vesuvius Black - Single SizesFrom £24 .98 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 1200 x 600mm 21.60m2

£26.85

30 £580 .02 per packinc VAT900 x 600mm 21.60m2

£24.98

40 £539 .58 per packinc VAT600 x 600mm 21.60m2

£33.37

60 Out of stock1200 x 600mm - Individual - 1 £20 .36 per slabinc VAT900 x 600mm - Individual - 1 £14 .26 per slabinc VAT600 x 600mm - Pack of 2 - Individual - 2 Out of stock -

Kandla Grey - Porcelain Paving

Kandla Grey - Porcelain PavingFrom £33 .86 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 900 x 600mm 21.60m2

£33.86

40 £731 .32 per packinc VAT900 x 600mm - Individual - 1 £20 .06 per slabinc VAT -

Quartz Grey - Porcelain Paving

Quartz Grey - Porcelain PavingFrom £29 .56 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 800 x 400mm 15.36m2

£29.56

48 £454 .01 per packinc VAT800 x 400mm - Individual - 1 £9 .44 per slabinc VAT -

Quartz Black - Porcelain Paving

Quartz Black - Porcelain PavingFrom £35 .96 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 800 x 400mm 15.36m2

£35.96

48 £552 .38 per packinc VAT800 x 400mm - Individual - 1 £11 .75 per slabinc VAT -

Deck Grey - Porcelain Paving

Deck Grey - Porcelain PavingFrom £35 .96 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 800 x 400mm 15.36m2

£35.96

48 £552 .38 per packinc VAT800 x 400mm - Individual - 1 £11 .75 per slabinc VAT -

Ireland Grey - Porcelain Paving

Ireland Grey - Porcelain PavingFrom £35 .96 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 800 x 400mm 15.36m2

£35.96

48 £552 .38 per packinc VAT800 x 400mm - Individual - 1 £11 .75 per slabinc VAT -

Silver Stone - Porcelain Paving

Silver Stone - Porcelain PavingFrom £27 .87 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 600 x 600mm 23.04m2

£27.87

64 £642 .02 per packinc VAT600 x 600mm - Individual - 1 £10 .63 per slabinc VAT -

Black Stone - Porcelain Paving

Black Stone - Porcelain PavingFrom £34 .53 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 600 x 600mm 23.04m2

£34.53

64 £795 .58 per packinc VAT600 x 600mm - Individual - 1 £13 .21 per slabinc VAT -

Rasa Crema - Porcelain Paving

Rasa Crema - Porcelain PavingFrom £34 .43 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 900 x 600mm 20.52m2

£34.43

38 £706 .51 per packinc VAT900 x 600mm - Individual - 1 £18 .85 per slabinc VAT -

Deck Brown - Porcelain Paving

Deck Brown - Porcelain PavingFrom £35 .96 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 800 x 400mm 15.36m2

£35.96

48 £552 .38 per packinc VAT800 x 400mm - Individual - 1 £11 .75 per slabinc VAT -

Blue - Porcelain Paving Tiles

Blue - Porcelain Paving TilesFrom £32 .71 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 900 x 600mm 16.22m2

£32.71

30 £530 .63 per packinc VAT900 x 600mm - Pack Of 2 - 1 £33 .67 per boxinc VAT -

Ivory - Porcelain Paving Tiles

Ivory - Porcelain Paving TilesFrom £32 .71 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 900 x 600mm 16.22m2

£32.71

30 £530 .63 per packinc VAT900 x 600mm - Pack Of 2 - 1 £33 .67 per slabinc VAT -

Rust - Porcelain Paving Tiles

Rust - Porcelain Paving TilesFrom £32 .71 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 900 x 600mm 16.22m2

£32.71

30 £530 .63 per packinc VAT900 x 600mm - Pack Of 2 - 1 £33 .67 per slabinc VAT -

Silver - Porcelain Paving Tiles

Silver - Porcelain Paving TilesFrom £31 .67 per m2

inc VATProduct OptionsName Pack size Per m2 Pcs per pack 900 x 600mm 25.92m2

£31.67

48 £820 .86 per packinc VAT900 x 600mm - Pack Of 2 - 1 £33 .67 per bundleinc VAT